Shop » Printer Parts » Extruders » LDO Orbiter V2.0 Extruder

LDO Orbiter V2.0 Extruder

$139.90 Original price was: $139.90.$115.00Current price is: $115.00.

One of the most expected project of 2022, the Orbiter v2.0

Only 1 left in stock

The new Orbiter v2.0 shares its concept design with the Orbiter v1.0 and 1.5 but it has been completely redesigned from scratch, improving every possible aspect we could think of.

Many new and improved design features:

- Shorter hardened drive gears 11mm vs 15mm manufactured by Bondtech

- Weight reduced to ~135 grams

- Smaller more compact dimensions (11.6% shorter)

- New motor design offers ~40% increase in extrusion force in real printing conditions and much improved acceleration performance

- Flipped drive gears – filament path closer to the extruder center for a more balanced design and perfect fit on delta printers as well

- Stainless steel filament exit guide with 0.2-0.3mm clearance to drive gears for best TPU printing experience and extreme wear resistance when using abrasive filaments.

- High temperature resistant housings, GPA12

- Machined PEEK secondary drive gear sleeve

- Tension mechanism with grab screw design

- Mounting screws in line with filament exit path – improving housing stiffness and easier mounting

- Perfectly aligned filament path

- New smaller and more stylish PTFE tube input coupler

- Motor position rotated by additional 10 degrees for easier maintenance and assembly

- Extremely low backlash ~0.06mm

- Filament sensor add on with auto load and unload button add on feature

- And many more small changes to improve mechanical accuracy and design look

Description

High precision direct drive extruder using custom made parts, manufactured by LDO Motors.

This is our finest direct drive extruder system in which LDO has integrated all what they learned about extruders in the past years.

PDF Download for more information

* The extruder itself without filament can handle acceleration up to 25000mm/s2. Adding weight of the filament it drags along its recommended to have acceleration limit set not above 8000mm/s2. To reduce clicking noise of the extruder (due to fast direction change) you may limit acceleration to 3000mm/s2

Reprap Configuration (Duet)

M350 E16 I1 ;micro stepping set to 16 with interpolation

M92 E690 ;steps/mm – you may need to finetune it

M203 E7200 ;max speed mm/min

M566 E300 ;instantaneous speed change mm/min

M201 E3000 ;acceleration mm/s2

M906 E1200 I10 ;motor current 1.2A idle current 10%

M572 D0 S0.02 ;pressure advance – to be calibrated

M207 S1.5 F7200 Z0.2 ;firmware retraction

Klipper Configuration

[extruder] microsteps: 16

full_steps_per_rotation: 200

rotation_distance: 4.637

nozzle_diameter: x.xx #define nozzle diameter

filament_diameter: 1.750

max_extrude_only_distance: 500

max_extrude_only_velocity: 120

pressure_advance: 0.025 #to be calibrated

pressure_advance_smooth_time: 0.03 #to be calibrated

[tmc2208 extruder] interpolate: true

run_current: 0.85 #**

hold_current: 0.100

sense_resistor: 0.11 #**

stealthchop_threshold: 0

driver_TBL: 0

driver_HEND: 6

driver_HSTRT: 7

driver_TOFF: 4

**Very important note!!!

Please make sure the sense resistor is set according to what you have on board.

TMC2130, TMC2208 and TMS2209 usually have 0.11Ω

TMC2660 have 0.051Ω

TMC5160 have usually 0.075Ω.

As an example, if you set by mistake the sense resistor to 0.11Ω instead of 0.051Ω the real current of the motor will be more than double, and the power injected in the motor more than four time higher, yes you read it correctly FOUR – AKA 4 times higher. 0.85A shall give a power loss of about 3.5W doubling the current will lead to >14W – this will melt all the plastic gearset before you even notice something is wrong!

How you can identify the sense resistor? It’s pretty easy, look for two identical resistors which are bigger than all the others onboard or around the stepper driver. See the examples in the next pictures.

Resistor marking examples:

R110 means 0.11Ω

R075 means 0.075Ω

R051 means 0.051Ω

Initial setup and test:

Set the current to a very low level 0.1-0.2A. Command extrusion, you should see the extruder turns but it skips steps very easy. This means you are tingling the right configuration, then set it to what it should be and check motor temperature, should not exceed 75°C at room temperature. If yes you might have misconfigured something (shunt / sense resistor) causing higher motor current than you think you’ve set.

Marlin Configuration:

There are two ways to configure Marlin for the Orbiter extruder.

1) Send configuration commands via user interface and save them to EEPROM.

2) Edit and change Marlin configuration files: Configuration.h and Configuration_adv.h recompile and reflash your microcontroller firmware.

Send the following commands via USB:

M350 E16 ;micro stepping set to 16

M92 E690 ;steps/mm – you may need to finetune it

M201 E3000 ;acceleration mm/s2

M203 E120 ;max speed mm/s

M205 E5 ;E jerk mm/s

M906 T0 E850 ;TMC motor RMS current in mA

M900 T0 K0.22 L0.02 ;linear advance values to be calibrated

M207 S1.5 F7200 Z0.2 ;firmware retraction

M500 ;save settings to EEPROM

More info:

https://www.thingiverse.com/thing:4725897

| Weight | 0.5 kg |

|---|---|

| Dimensions | 15 × 15 × 10 cm |

| Brand |

Related products

- Quick ViewAdd to cart DetailsBuy Now

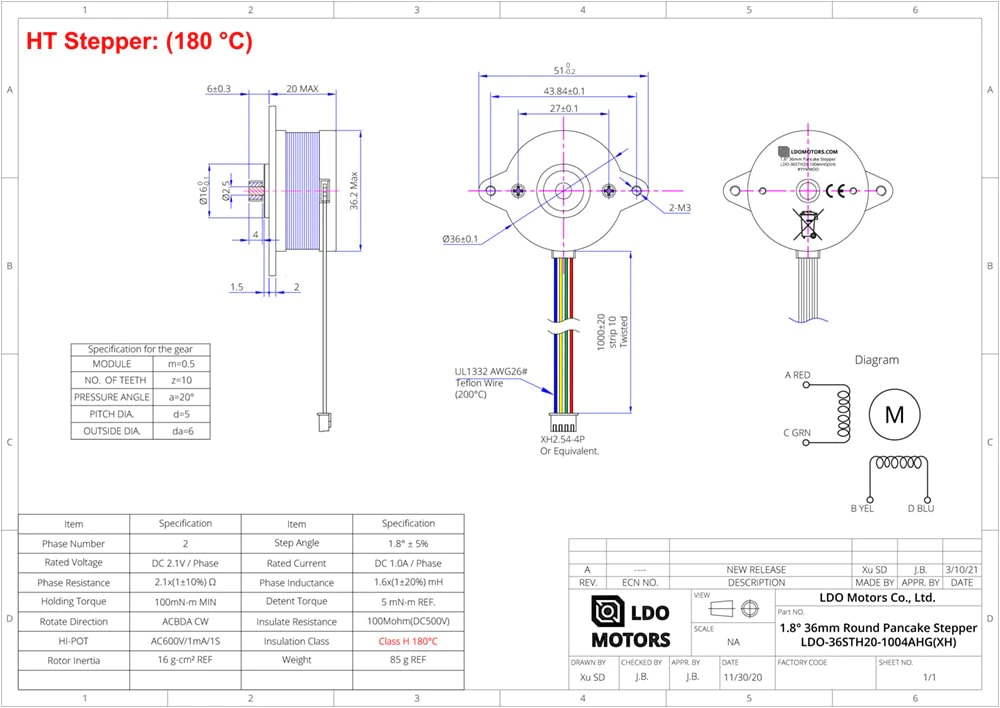

New motor design. Extruder Motor stays much cooler during printing. NOT suited for x and y axis. COOL POWER stepper motor. Compatible with PRUSA MK3 extruder motor.

- Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page Details

Capricorn Premium bowden Tubing is enhanced with a proprietary blend of high performance additives.

- Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page Details

Dual Drive Extruder for high performance – Cloned BMB

- Quick ViewAdd to cart DetailsBuy Now

Nema 17 High resolution 1.8° pancake stepper motor. Perfect fit for BMG / Prusa extruder upgrades.

Reviews

There are no reviews yet.