Shop » Printer Parts » Extruders » Phaetus APUS Extruder

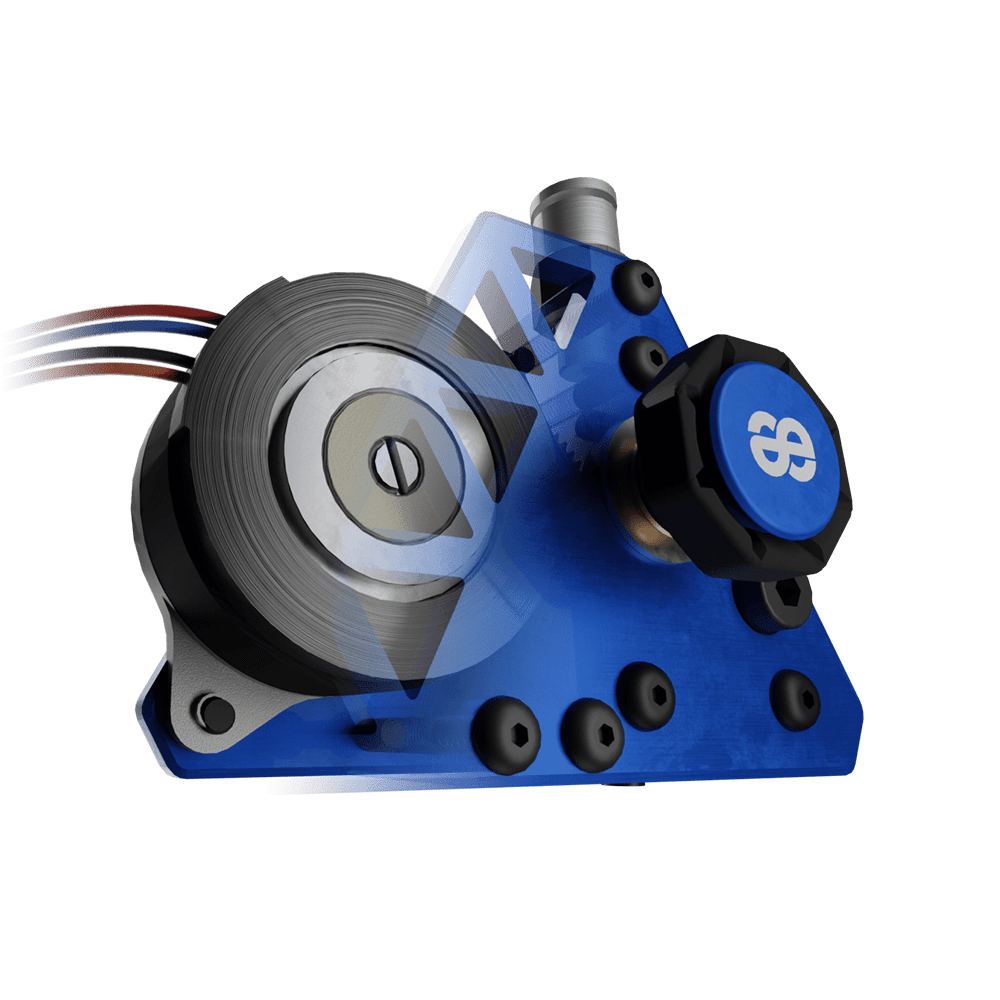

Phaetus APUS Extruder

$84.90 Original price was: $84.90.$65.90Current price is: $65.90.

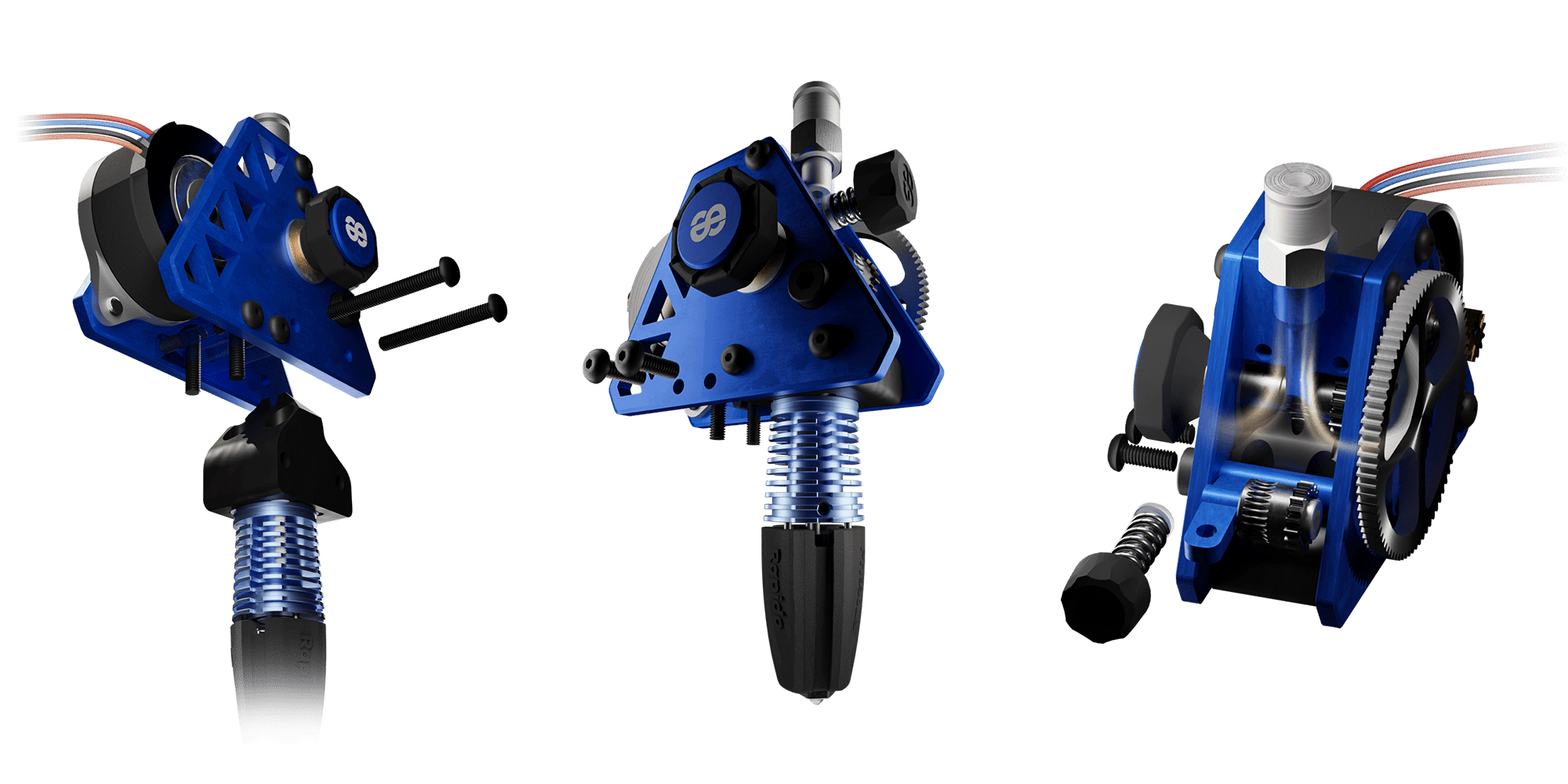

A 155g light weight all metal design with a Nema 14 stepper motor, gives the APUS extruder a perfect balance of rigidity and weight. The aluminium frame improves the heat dissipation of the Nema 14 stepper motor

Only 2 left in stock

APUS Extruder

A 155g light weight all metal design with a Nema 14 stepper motor, gives the extruder a perfect balance of rigidity and weight. The aluminium frame improves the heat dissipation of the Nema 14 stepper motor.

This is a high-end extruder for industrial filaments.

- Filament size: 1.75mm

- Product Size (mm): 67*64*42

- Product Net Weight: 155g

- Product Appearance: Blue

Compatible with all thermoplastic filaments including but not limited to:

- PLA

- ABS

- PETG

- TPU

- PP

- PC

- PA

- PEEK

- PEI

As well as typical composite fibre filaments such as:

- PLA-CF

- ABS-CF

- PETG-CF

- PA-CF/GF

Composite filaments such as steel, wood, boron carbide, tungsten and fluorescence materials can be processed by the extruder as well.

3-Screws-System

Easy maintenance by removing only three screws

Quick swap system

The standard hotend attachment is compatible with hotends from Phaetus & DropEffect.

The hotend attachment can be redesigned and 3D printed to fit a multitude of hotends on the market.

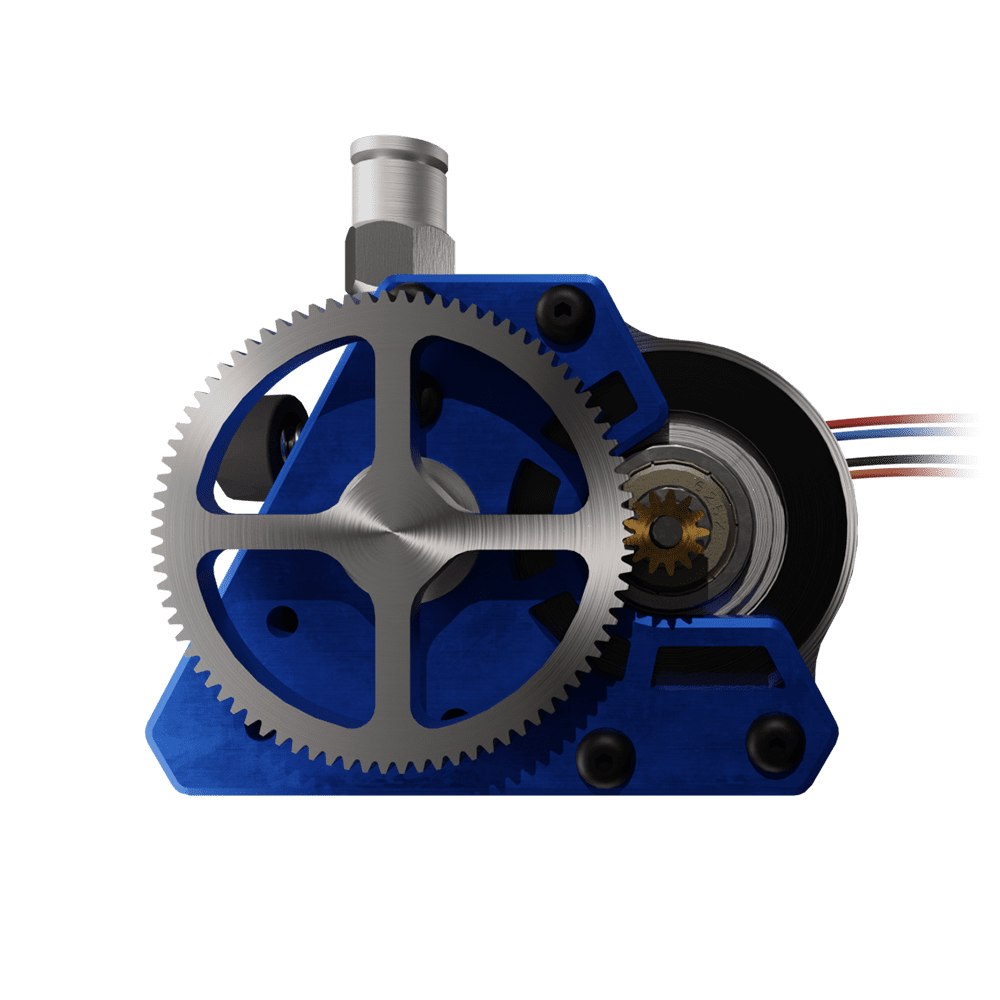

Small Nema 14 stepper motor

Rated Current: 1.0 A.

Holding Torque: 0.12 Nm

Temperature Rise: Less Than 55℃

Max Operating Temperature: 130℃

Weight: 85g

155g light weight all metal design

155g light weight design of the aluminium frame ensures heat dissipation of the stepper motor.

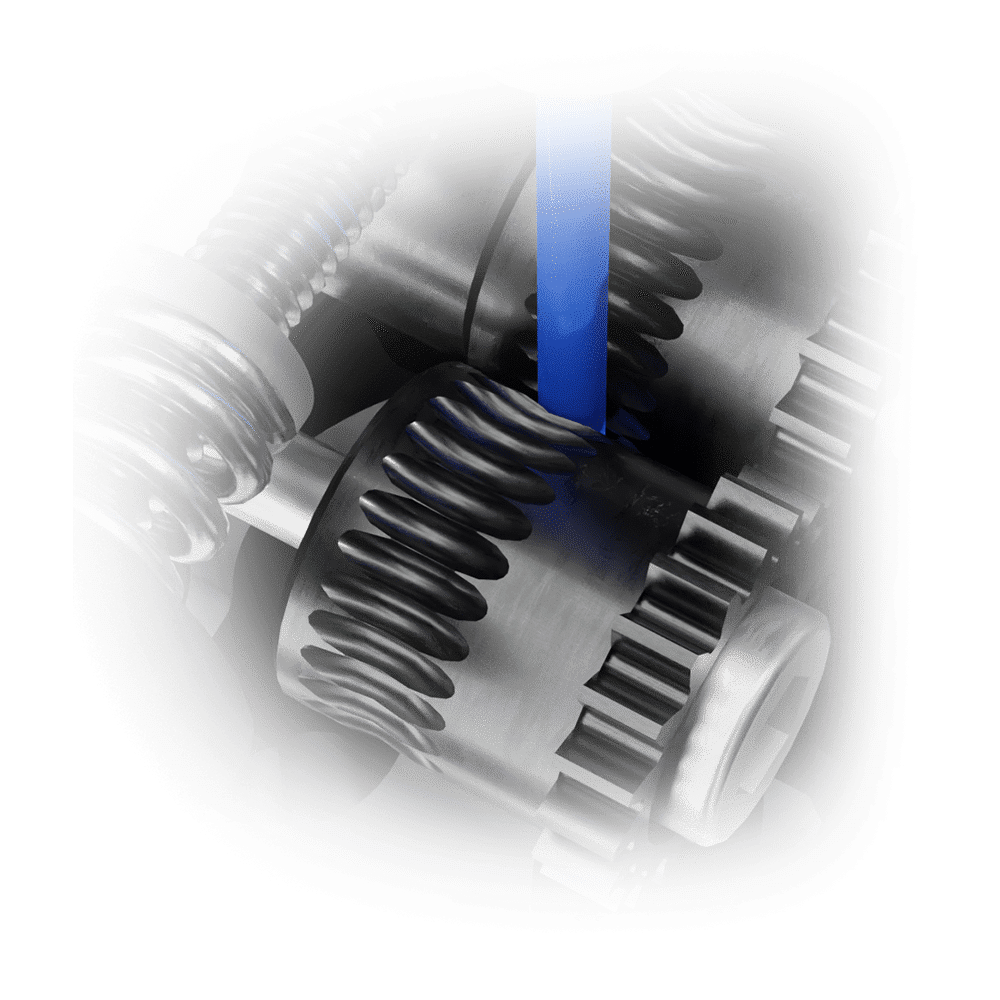

Optimized RNC Dual Drive Gears

Whole Hardness: HRC58+ RNC

Coating Hardness: HV3300

Polished Surface Area Dual Drive

Gears For A Stable Extrusion

6.3 : 1 Gear ratio

6.3 : 1 Gear ratio to ensure high torque

Manual wheel design for easy filament loading and unloading

Easy loading and unloading of filament using the manual wheel

Aluminum frame

High rigidity

Aluminium gear

Ensure efficient torque transfer

Hardened Steel Dual Drive gear

Excellent grip and wear resistance

Aluminium Idler arm

Ensure good gear contact

Aluminium filament guide

High wear resistance

Accessories List

- Motor Extension Cable -5cm(Molex Micro Fit 3.0-DuPont TJC8-4)

- Motor Extension Cable -5cm(Molex Micro Fit 3.0-JSTXHP-4)

- H2.0 Hex Key

- H2.5 Hex Key

- Button Head Socket Cap Screw M3x12

- Cup Head Screw M2.5×12

Optimized RNC Dual Drive Gears

The APUS extruder has gear ratio of 6.3/1 and the gears have a co-prime number of teeth for an optimal gear design. The teeth on the Dual Drive gear system were optimized to perfectly grip all kinds of filaments and are RNC hardened. This hardening process enhances the wear resistance and gives the Dual Drive gears a polished surface. A tightly constricted filament path makes the extruder more reactive and as such ensures that the extrusion process is as consistent as possible. Using the manual wheel, the user can easily load and unload the filament without having to rely on a Gcode load and unload macros.

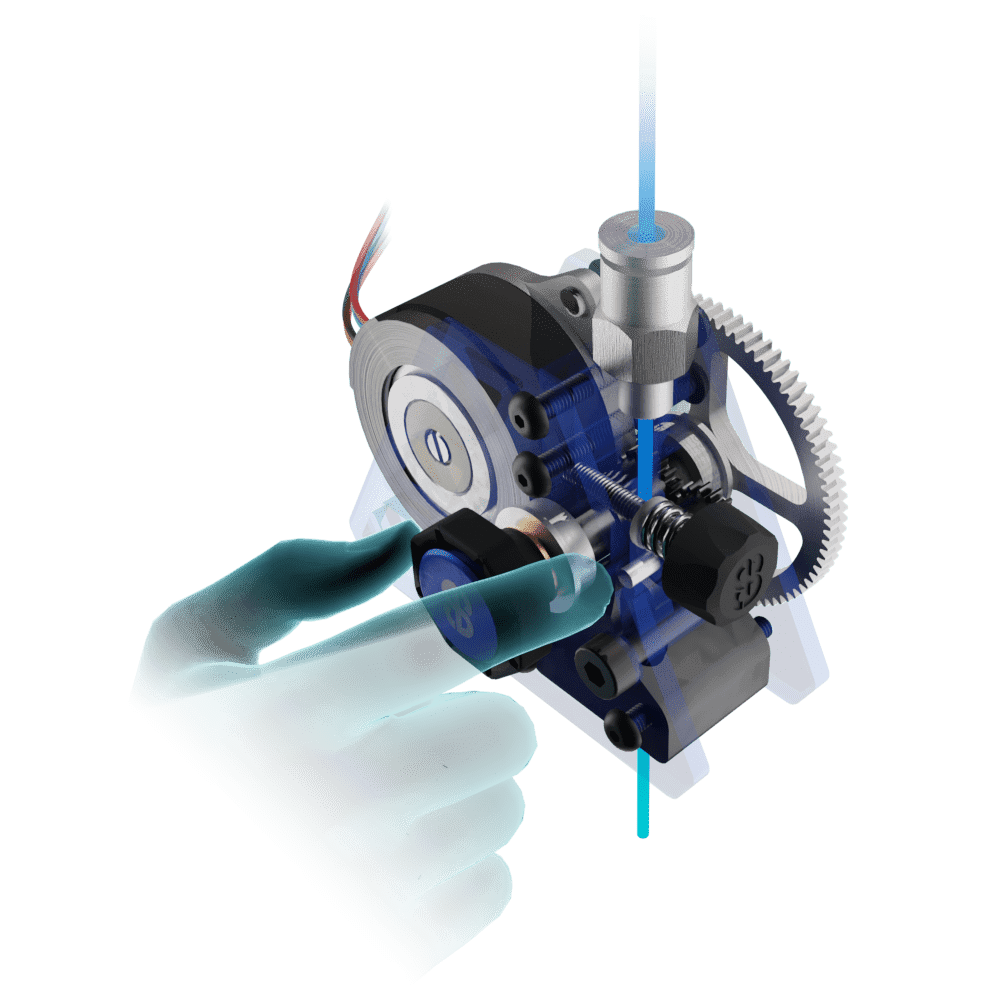

Universal Hotend Mounting System

In the modern 3D printing era high-speed printing is becoming more important. This is why the APUS extruder was designed in such a way that the centre of mass is as close as possible to the mounting system, even when a hotend is installed. This ensure that the moment acting on the mounting system is small. The extruder adopts the “three screw system”: two screws to remove the hotend and one screw to loosen the Idler. With this the user has complete access to the filament path. This system also allows to “quick swap” hotends conveniently. This ”quick swap system” can be 3D printed and as such it can be redesigned to fit any kind of hotend.

| Weight | 0.3 kg |

|---|---|

| Dimensions | 15 × 15 × 5 cm |

| Brand |

Related products

- Quick ViewAdd to cart DetailsBuy Now

ePLA-LW is mainly used for lightweight parts and is widely used in fields such as DIY model aeroplanes, drones, and COSPLAY props.

- Quick View

- Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page Details

An all metal upgrade kit for the Creality Ender extruder

- Quick ViewAdd to cart DetailsBuy Now

Polymaker PolyLite™ LW-PLA is a special foamed PLA designed to print with similar settings as regular PLA but with half the weight.

Reviews

There are no reviews yet.