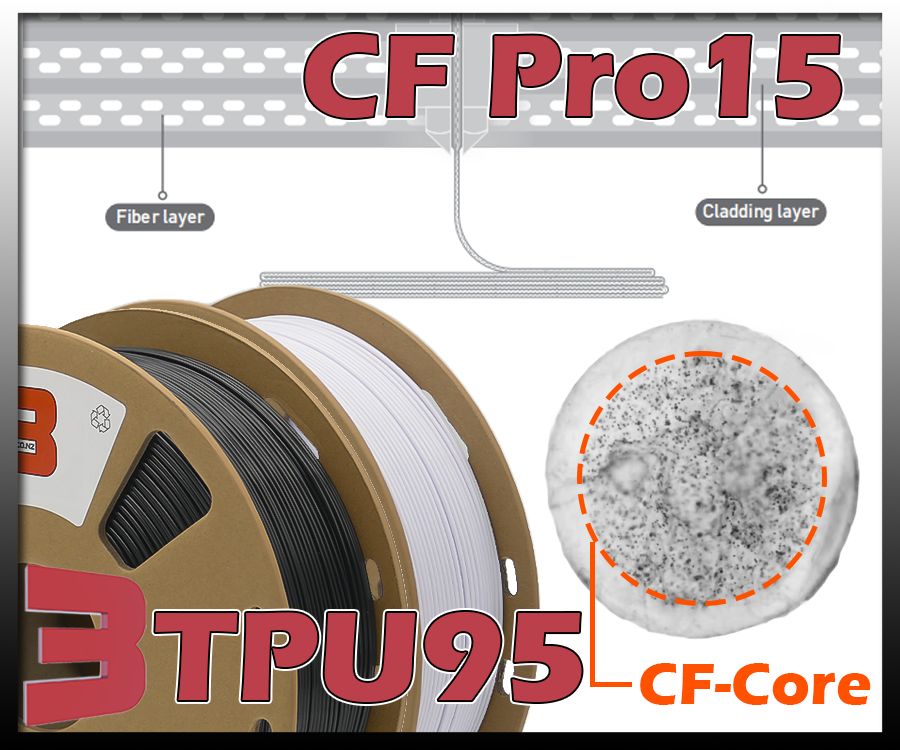

Shop » Composite » Carbon Fibre » TPU-CF Pro15 – Co-Extruded Carbon Fibre Enhanced TPU 95A Filament

TPU-CF Pro15 – Co-Extruded Carbon Fibre Enhanced TPU 95A Filament

$75.90

TPU-CF Pro15 filament is an engineering-grade, carbon fiber-reinforced PETG material with a cutting-edge skin-core structure.

1kg - Black, White

TPU+CF (Co-Extruded)

The TPU-CF Pro15 filament is an engineering-grade, carbon fiber-reinforced TPU material featuring a state-of-the-art skin-core structure. The core is made of TPU reinforced with 15% chopped carbon fiber for enhanced strength and rigidity, while the outer layer consists of unfilled TPU resin, delivering excellent flexibility and superior bond strength.

During printing, the polymer fluid maintains a laminar flow state through the throat and nozzle, preserving the filament’s unique skin-core structure even after extrusion. This innovative design provides several significant advantages:

- Enhanced Mechanical Properties: Combines the flexibility and resilience of TPU with the added strength, wear resistance, and dimensional stability of carbon fiber reinforcement.

- Stronger Interlayer Adhesion: Solves the common issue of weak bonding between layers in fiber-reinforced materials, ensuring printed parts exhibit exceptional durability and elasticity.

- Superior Surface Finish: The unfilled TPU outer layer prevents floating fibers, resulting in a smooth, matte texture that improves both the appearance and performance of the printed parts.

Made with premium carbon fiber—not powder or dust— TPU-CF Pro15 delivers all the benefits of carbon fiber reinforcement while preserving TPU’s signature flexibility. Its skin-core structure minimizes shrinkage, resists warping, and provides unmatched interlayer strength, making it an excellent choice for applications requiring durable, flexible, and aesthetically refined parts, such as gaskets, seals, or functional prototypes.

Printing Tips:

The filament is designed to maintain its core-skin structure during extrusion, leveraging the stable laminar flow state of the molten polymer. However, at excessively high printing speeds, the melt flow can become unstable, disrupting the core-skin structure. This instability can lead to rough or uneven surfaces on the printed part.

To prevent this issue and maintain optimal print quality, it is recommended to either increase the printing temperature or reduce the extrusion speed to restore stable laminar flow and preserve the filament’s core-skin integrity.

Nozzle: We currently recommend a hardened steel nozzle with a minimum diameter of 0.4mm.

Diameter 1.75mm2 ±0.03

Density 1.24 ±0.05g/cm2

Print Temp 215-250ºC

Hot bed 50-90ºC (required)

Surface Blue tape, glue stick, PEI

To ensure optimal adhesion of TPU filament with carbon fiber, it is recommended to apply an adhesive (such as glue stick or hairspray) to the print bed to help the first layer adhere properly. While using a heated bed is not mandatory, maintaining a bed temperature between 45°C and 60°C is recommended for better results. The ideal printing temperature ranges from 215°C to 245°C, with the cooling fan set to 100% for consistent layer cooling.

If you encounter printing issues, such as filament slipping in the extruder or inconsistent extrusion:

- Disable Retraction: This can help prevent the flexible filament from slipping or binding in the extruder.

- Increase Flow Rate: Adjust the flow rate slightly to compensate for any intermittent extrusion and ensure smooth printing.

These settings will help achieve better results, ensuring both proper adhesion and consistent extrusion when working with TPU filament reinforced with carbon fiber.

| Weight | 1 kg |

|---|---|

| Brand | |

| Colour | Black, White |

| Material | TPU-CF |

Related products

- Quick ViewAdd to cart DetailsBuy Now

Translucent PLA is a versatile 3D printer filament that produces semi-transparent prints with a glossy finish. Ideal for creating light-diffusing parts, decorative objects, and visual prototypes.

- Quick ViewAdd to cart DetailsBuy Now

Translucent PLA is a versatile 3D printer filament that produces semi-transparent prints with a glossy finish. Ideal for creating light-diffusing parts, decorative objects, and visual prototypes.

- Quick ViewAdd to cart DetailsBuy Now

Translucent PLA is a versatile 3D printer filament that produces semi-transparent prints with a glossy finish. Ideal for creating light-diffusing parts, decorative objects, and visual prototypes.

- Quick ViewAdd to cart DetailsBuy Now

Multi-Colour Rainbow quality 1.75mm filament comes on an eco friendly vacuum packed cardboard reel.